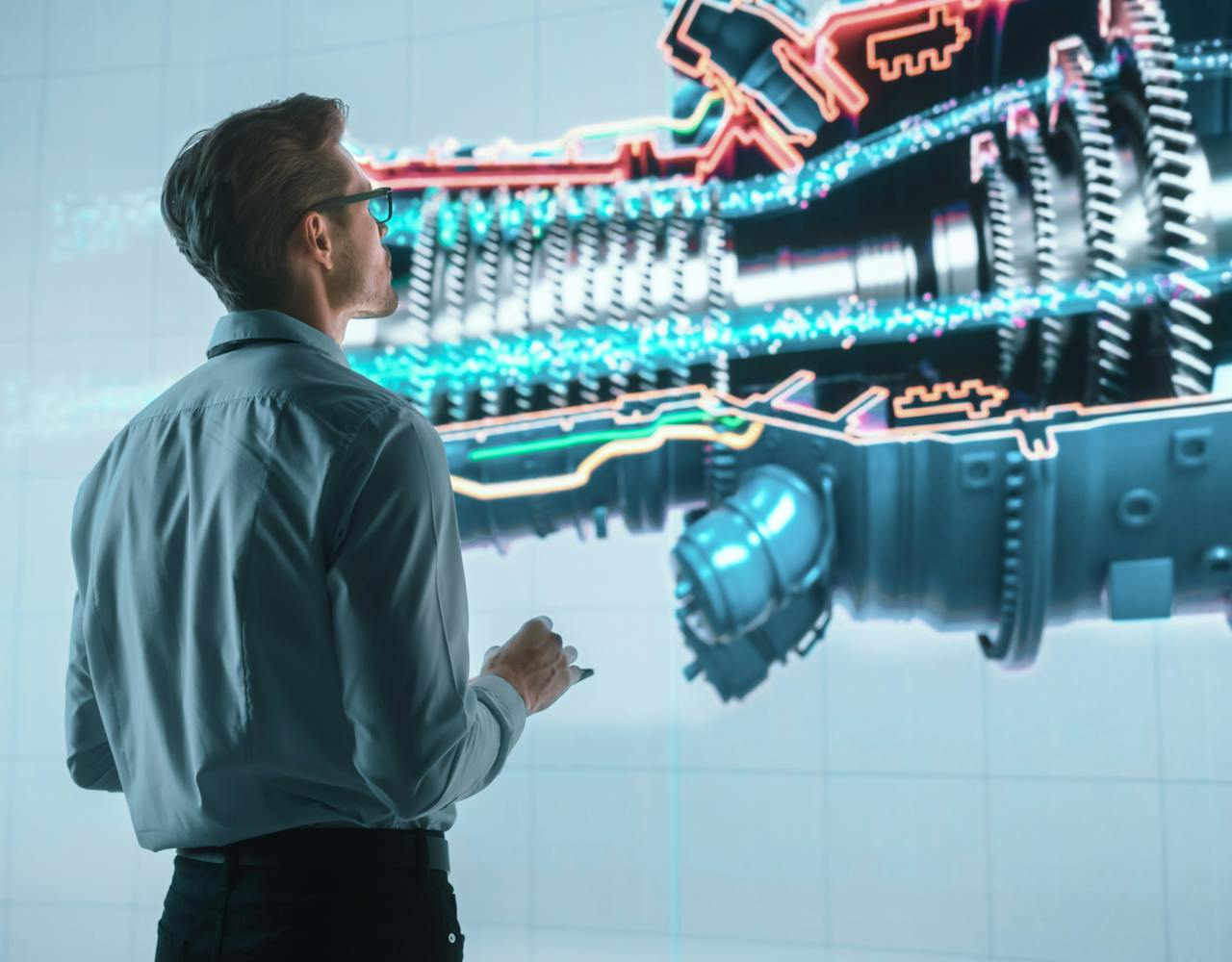

Simulation

Simulation is the virtual imitation of a physical product (that often does not even exist yet). This allows the operation, quality, reliability, and behavior to be examined and digitally analyzed.

Fewer prototypes, more time

Sometimes it is not possible or appropriate to test a product or process in reality. In this case, simulation is an effective solution to validate your product. With CAE solutions (Computer-Aided Engineering) you need fewer or no physical prototypes. This way, you save costs and time to validate the proper operation of a product. Simulation is also used to validate the proper production of components, to produce faster, to eliminate errors and to prevent that production machines break down.

Applications of Simulation

- Accelerating innovation

- Analyzing the operation of a product

- Analyzing certain problems in new or existing products

- Evaluating if a certain component is strong enough

- Increasing the performance and reliability of a product

- Evaluating the impact and feasibility of the proposed product adjustments

- Avoiding errors in CNC (production) programs

- Preventing that a product is lost or a production machine breaks down

- Optimizing CNC programs in order to produce parts faster