What is industry 4.0 and how can you implement it?

Before you understand how you could exactly implement ‘industry 4.0’, you should know what the word exactly means, because it’s rather a broad term.

What is industry 4.0?

In the first place, industry 4.0 refers to the digitization and automizing of the industry. This mainly concerns production processes. It is completely about making the production process more smoothly by using data. Moreover, there are many different production systems that collaborate. To make this possible, IoT plays a crucial role. The Internet of Things guarantees that production systems have a better communication with each other, in a digital way. You could compare this with a system in which you ask your smartphone to turn on the lights, before you get home. Or when you turn off the alarm system from your car, by using your mobile phone. Why is industry 4.0 gaining popularity? The production environment is continuously changing. Also, there is an increasing demand of tailor-made production. Today’s customers simply expect more.

Characteristics of industry 4.0

Smart industry or industry 4.0 has a few specific characteristics:

- Automation by means of software solutions

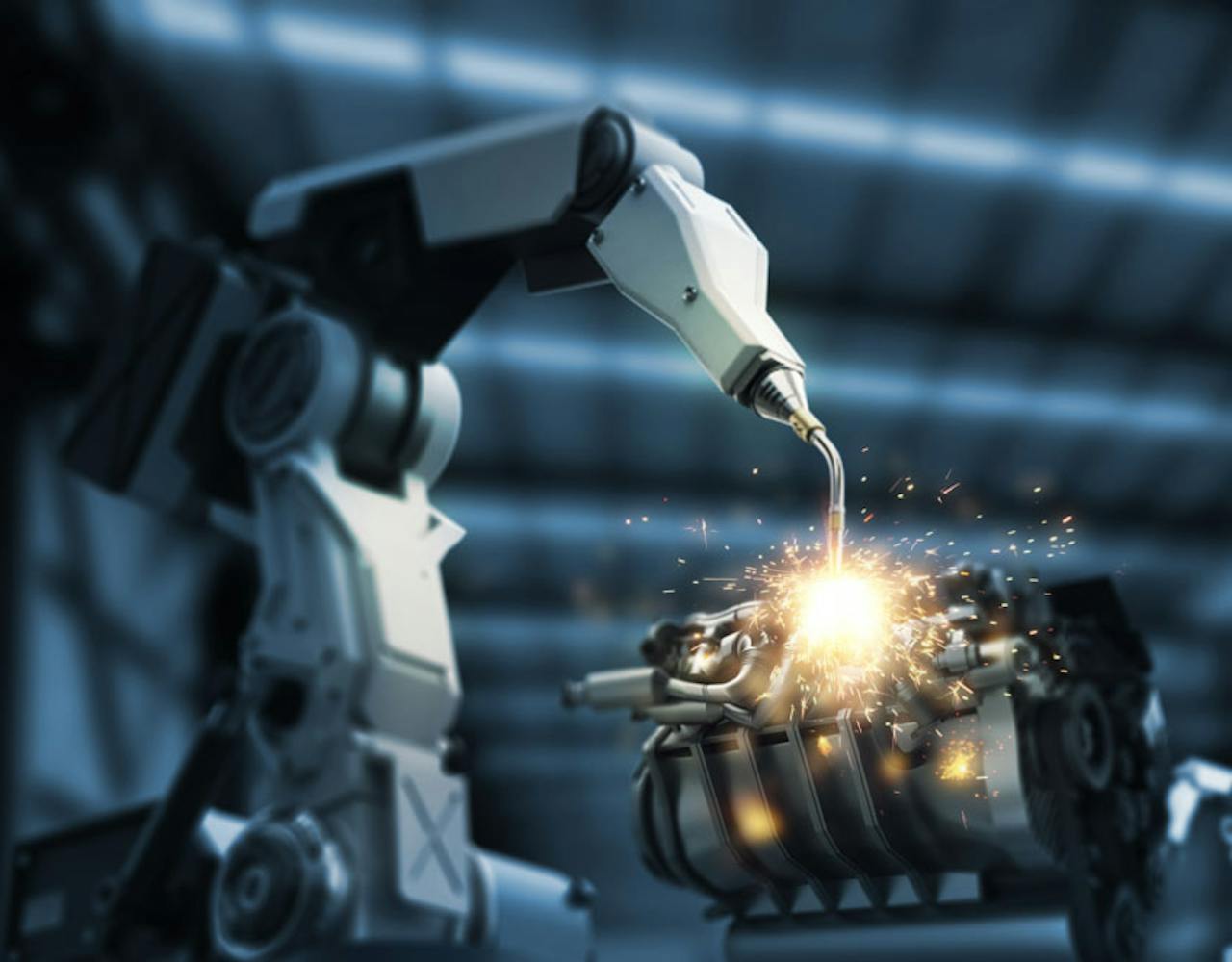

- Robotisation: machines that operate and take decisions (semi-)autonomously

- The use of new technologies, like Big Data, AR, IoT and the Cloud

- A bridge between the physical world and the digital world (IIoT)

- A focus on smarter machines

- A faster production

- Personalized products

- Improved models and control systems

- An increased capacity of production companies

- Less need of human activities

In short, it is all about a complete digitization of the industry. No wonder people call this kind of industry also ‘a smart industry’ or even ‘the 4th industrial revolution’. As a matter of fact, a machine can readout what exactly has to happen to set the production process in motion. Hence, it communicates with different production systems.

Industry 4.0 within the manufacturing industry

The term ‘industry 4.0’ is especially associated with the manufacturing industry. The world of the manufacturing industry is evolving rapidly. That is why it is extremely important to stay one step ahead of the competition. Therefore, the combination of software, data and hardware in this industry is very crucial. Think for instance of the automotive sector or companies that are active in 3D printing.

Applications of industry 4.0

The 4th industrial revolution takes place in different fields, by various applications:

Augmented Reality

- Order picking of certain articles and preparing them automatically? Perfectly possible with industry 4.0!

- Employees could get real-time information, so working procedures could run more smoothly.

- Sending instructions for repairs, so that employees are able to reduce their workload.

3D-printing

- Making prototypes for separate parts and produce them.

- Production of custom-made products which reduce the costs.

Internet of Things

- Man and machine work closely together. Different machines manage to communicate in a better way with each other.

- Machines know which production steps have to be taken exactly in certain situations.

- Real-time reactions save time and money.

Integration of systems

- A better collaboration occurs between different departments within a single organization.

- Universal data networks are being developed. Therefore, companies work better together.

Simulation

- Machines could be tested, before the production even begins. Therefore, you will lose less time and you are able to ameliorate the quality.

- Quick tests within a virtual world allow a faster innovation.

Robots

- A lot of industries make use of robots that can perform complex tasks.

- Robots get more and more autonomous, flexible and smarter.

- A better collaboration with people.

Big data

- An optimization of the production quality because of a thorough analysis.

- Energy saving.

- Responding to market trends and preferences of customers.

- Detect possible defects more quickly.

Are you curious about the possibilities of industry 4.0 for your company? And would you like to know what our experts have in mind regarding your organization? Please do not hesitate to contact us.