Indispensable manufacturing trends in 2023

What are the manufacturing trends of 2023? How could you, as a company, keep pace with the competition and remain successful? We’ll summarize the trends.

Manufacturing 2023

Smart manufacturing is evolving in record time. Companies aim for taking challenges, ameliorating production processes and finding a way to work more efficiently. In this, technological progress, market needs and objectives of the company play a significant role.

Regarding smart manufacturing we could expect the following 7 trends in 2023.

3D-printing

It has become clear that 3D printing (in which materials are produced in different layers) will influence the production in the next few years. 3D printing offers a lot of advantages: better performance, freedom in design, higher productivity and a faster time-to-market are only a few examples. Many industries count on those progressive 3D techniques for the performance of their activities. Think of defense, aerospace and car manufacturing.

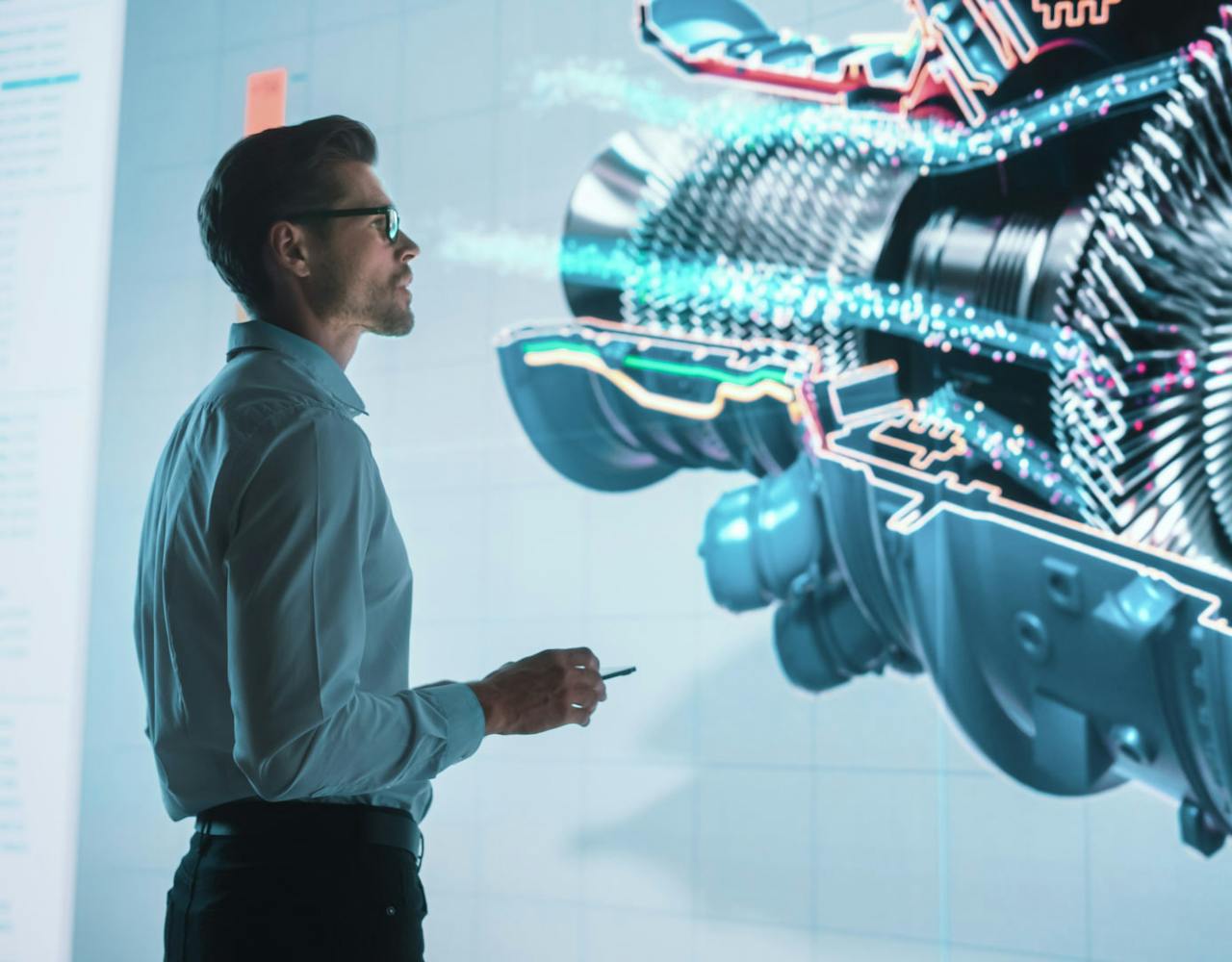

Prediction in maintenance with Digital Twin

Maintenance of machines is important in any case. But, what if you could predict in advance what needs to happen and when? Today it is even more important to predict when problems could arise and which defects are probable to occur during the production process. In this way, you won’t lose any precious time with failure of machines or repairs with sky-high costs. Digital Twin is a crucial step to switch from a preventive maintenance to a predictive maintenance.

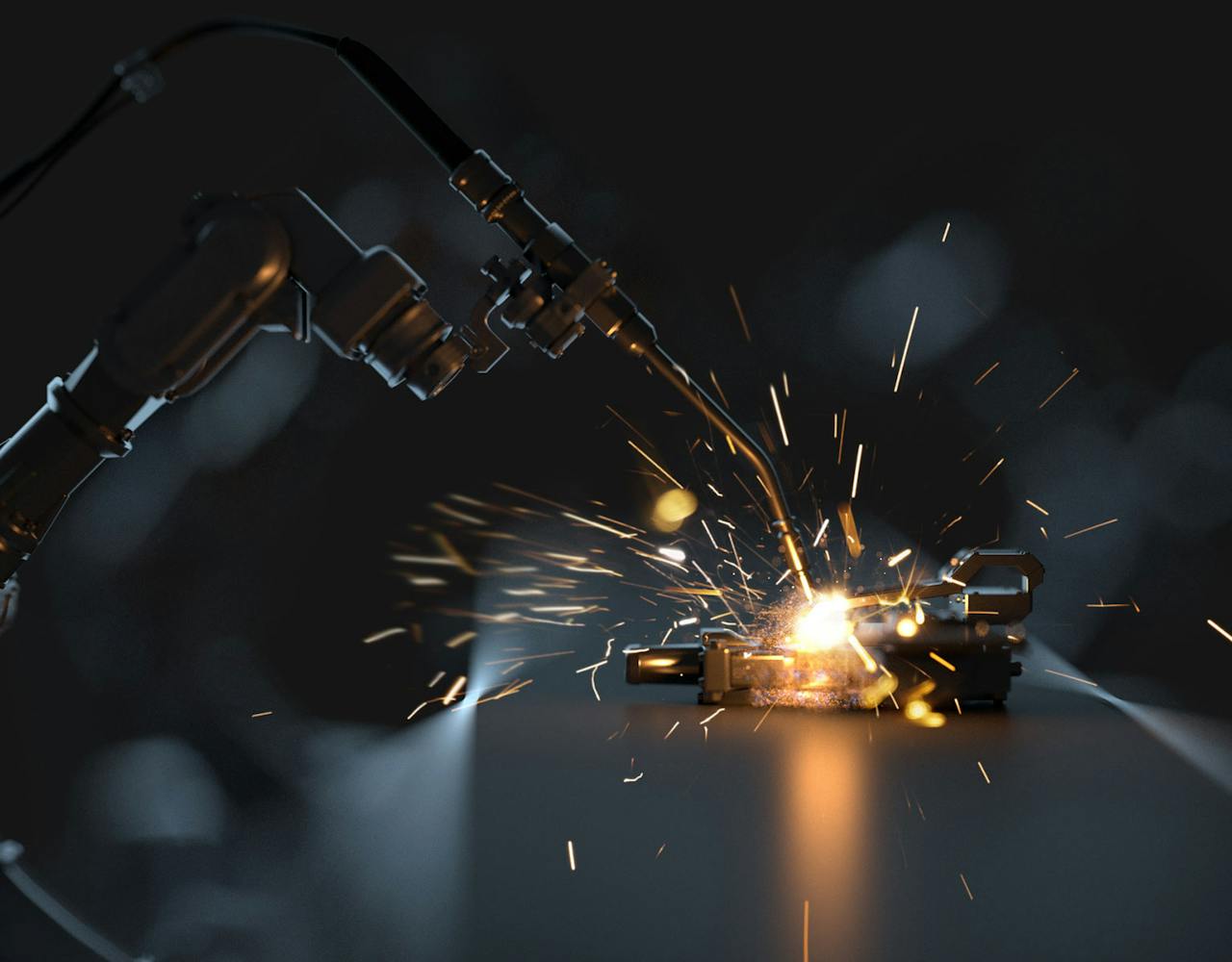

Increasing automation

Not a single entrepreneur is waiting for shortage of staff or waste of time. Automation guarantees peace of mind. Think about AI, machine learning and smart machines. Although automation will replace human forces on the one hand, it will ask for other human forces on the other hand. The focus moves to technically skilled experts. Man and machine collaborate.

Industrial Internet of Things

Sensoring, monitoring at a distance, a better connection between different devices and Internet of Things become more and more important. They guarantee a better and more reliable communication. Moreover, companies are able to innovate in a more efficient way.

Virtual world

Nowadays we could hardly neglect digital twins, machine learning, AI, AR and VR in modern businesses, especially in the world of manufacturing industry. Virtual operation is not just a trend. It ameliorates the production process, the flexibility and safety of the employees. Moreover, virtual techniques have proven their worth, more than ever, during the corona era. Monitoring, maintenance and operation of machines at a distance suddenly became a necessity.

Evaluation with simulation

Today, simulation is not only used for the validation of designs. Even during the design process, simulations are frequently used. This way, we know how a design would react in reality. Hence, you save money and time.

Sustainability

For many years, sustainability plays an important role. But, meanwhile, as an entrepreneur, it has almost become a necessity to do business in a sustainable and responsible way, with respect for the environment. The costs of energy and materials are constantly rising. No wonder ambitious companies are attracted by sustainable solutions.

Would you like to know how you could keep pace with the competition? And would you like to get professional advice from our experts? Please contact us.